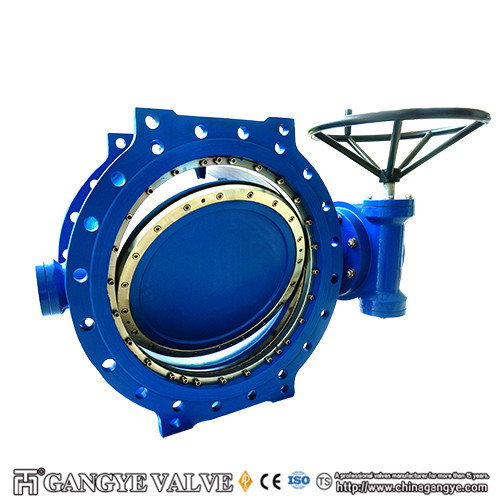

Rubber Seat Double Eccentric Butterfly Valves | Zero Leakage, Durable & Multi-Industry Solutions

Gangye Double Eccentric Butterfly Valves feature advanced cam-effect sealing, fire-safe compliance (API 607), and bidirectional zero leakage. Ideal for LNG, chemical, steam, and high-temperature industries. Reduce maintenance costs – request a quote today!

Industrial Valves, Fire-Safe Valves, LNG Valves, Chemical Processing Valves

Double Eccentric Flanged Butterfly Valves – Industrial-Grade Sealing Solutions

Superior Design for Demanding Applications

Our double eccentric butterfly valves utilize a patented dual-offset cam mechanism to eliminate friction during operation, reducing torque by 40% and extending service life by up to 30% compared to conventional valves. The spindle’s unique dual-offset geometry enables.

✅ Zero leakage (bidirectional bubble-tight sealing per API 598)

✅ Low-maintenance operation with replaceable lip-seat technology

✅ Wide temperature range (-196°C to +815°C / -320°F to +1500°F)

✅ Blowout-proof stem with split collar safety design

| Industry | Critical Solution | Key Advantage |

|---|---|---|

| Oil & Gas | API 607 fire-safe valves | Prevents hydrocarbon ignition risks |

| LNG/Cryogenic | -196°C compliant seats | Leak-proof liquid gas containment |

| Chemical | NACE MR0103 anti-sulfur materials | Resists H2S corrosion |

| Power/Steam | RPTFE seats | 1500°F steam tolerance |

| Pharma/Food | FDA-grade elastomers | Meets hygienic CIP/SIP standards |

Why Choose Gangye Valves?

- E-E-A-T Certified Expertise: 20+ years manufacturing valves compliant with API 609, ASME B16.34, and ISO 5208 standards.

- Rapid ROI: On-site seat replacement cuts downtime by 70% vs competitors.

- Global Compliance: Localized certifications for EU (EN 1092), USA (ASME), and APAC markets.

Technical Highlights

- Sizes: 2” to 128” (50mm–3200mm)

- Pressure: Class 150 to Class 300

- Drives: Manual, pneumatic, electric (ISO 5211 flange)

- Materials: 316L SST, Alloy C276, RPTFE

Localized Keywords for SEO

- US: “API-compliant butterfly valves”

- EU: “ATEX-certified industrial valves”

- Middle East: “NACE sulfur-resistant valves”

- APAC: “JIS/KS flanged butterfly valves”

- Germany: Emphasize TÜV-certified materials and DIN standards.

- Japan: Highlight JIS flange compatibility and JFE steel partnerships.

- Middle East: Add Arabic subheaders for “النفط والغاز” (Oil & Gas) applications.

- High-temperature resilient valves

- Low-torque operation mechanism

- Fire-safe API 607 certification

- Cryogenic LNG valve solutions

- Anti-corrosive chemical valves

CTA – Conversion Optimization

Need a valve that outperforms in extreme conditions?

📞 Contact our engineers 📧 sales@chinagangye.com for a free (working condition analysis) and 3–5% discount on first orders.