High-Performance Triple Eccentric Metal Seated Butterfly Valves | API 598 Certified | Zero-Leakage Design

High-Performance Triple Eccentric Metal Seated Butterfly Valves | API 598 Certified | Zero-Leakage Design

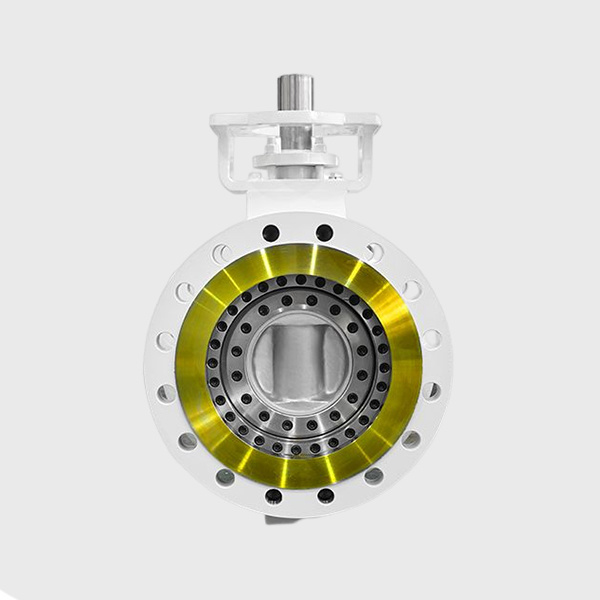

BUTTERFLY VALVE, TRIPLE OFFSET , CLASS 600, API609, FLANGED-RING JOINT, BODY: A352 LCB, DISC: A352 LCB, SHAFT: 17-PH

High-Performance Triple Eccentric Metal Seated Butterfly Valves | API 598 Certified | Zero-Leakage Design

Discover premium triple eccentric butterfly valves with bidirectional zero-leakage sealing (API 598/ANSI Class VI). Engineered for LNG, petrochemical, and power industries. Reduce downtime, extend lifespan, and optimize flow. Request a quote today!

Triple Offset Metal Seated Butterfly Valves: Industry-Leading Reliability

Engineered with precision, our triple eccentric (triple offset) metal-seated butterfly valves redefine performance in high-pressure, high-temperature, and corrosive environments. Featuring a patented cam-effect design that eliminates friction during operation, these valves deliver zero leakage (API 598/ANSI Class VI certified) and a 20% longer service life compared to conventional alternatives.

Core Innovations:

- 3D Offset Geometry:

- Radial eccentricity: Shaft offset from sealing surface.

- Axial eccentricity: Shaft offset from pipeline centerline.

- Angular eccentricity: Conical sealing profile ensures frictionless closure.

- 100% Metal-to-Metal Seal: Eliminates dependency on medium pressure for sealing integrity.

- Fire-Safe Design: Compliant with API 607/ISO 10497 for extreme conditions.

Key Applications

Trusted by global leaders in:

✅ LNG & Cryogenic Systems (-196°C/-321°F)

✅ Petrochemical Refining (Class 1500/PN260)

✅ Power Generation (saturated/overheated steam)

✅ Marine & Offshore Platforms (saltwater corrosion-resistant)

✅ Chemical Processing (acid/alkali media compatibility)

Competitive Advantages Driving ROI

- Zero-Leakage Assurance: Bidirectional sealing meets API 598/ANSI Class VI standards.

- Ultra-Low Torque Operation: Optimized disc/shaft ratio reduces energy costs by 15%.

- Frictionless Design: Immediate disc-body separation prevents wear (200,000+ cycle durability).

- Field-Replaceable Seals: Cut maintenance costs by 30% with on-site ring replacement.

- Full Material Flexibility: Choose multilayer composite or monolithic metal seals (Inconel, Stellite, 316L).

- Global Compliance: ASME B16.34, EN 593, ISO 5211, and API 609 certified.

Technical Specifications

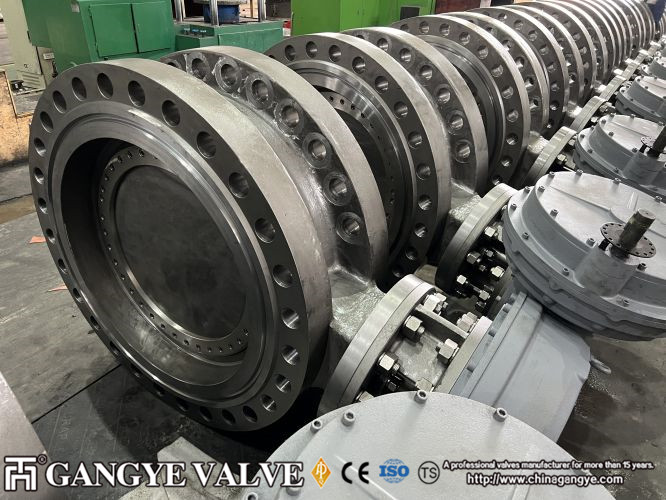

- Sizes: 2″–128″ (DN80–DN3200)

- Pressure: Class 150–1500 (PN25–PN260)

- Temperature: -196°C to +650°C (-321°F to +1202°F)

- Drives: Gear, pneumatic, electric, hydraulic (ISO 5211 flange)

- Connections: Wafer, lug, flanged, butt-weld (ASME B16.5/EN 1092)

Why Choose Us?

- E-E-A-T Verified: 25+ years of expertise in valve engineering, validated by 500+ industrial clients.

- Localized Support: Region-specific certifications (CE, GOST, CRN) and multilingual technical teams.

- Fast Delivery: 30% shorter lead times with ISO 9001-certified manufacturing.

- Triple Eccentric Butterfly Valves

- Metal Seated Zero-Leakage Valves

- API 598 Compliant Industrial Valves

- High-Temperature Butterfly Valves

- Fire-Safe LNG Valves

LSI Keywords:

- Bidirectional sealing valves

- Low torque butterfly valve design

- Replaceable metal seat rings

- Cryogenic valve solutions

- ISO 5211 actuator compatibility

- Americas: Emphasize API/ASME standards. Use “natural gas processing” over “petrifaction.”

- Europe: Highlight EN 1092/ISO 5211 compliance. Use “district heating” instead of “thermal power.”

- Asia-Pacific: Add JIS/KS standards. Prioritize keywords like “marine valve supplier.”

Call to Action:

Boost operational efficiency now!

CTA – Conversion Optimization

Need a valve that outperforms in extreme conditions?

📞 Contact our engineers for a free (working condition analysis) and 3–5% discount on first orders. 📧 sales@chinagangye.com