Gangye’s API 600-certified forged steel check valves ensure leak-proof performance for pipelines up to ANSI 800#. ISO 9001, CE, TS certified. 18-month warranty.

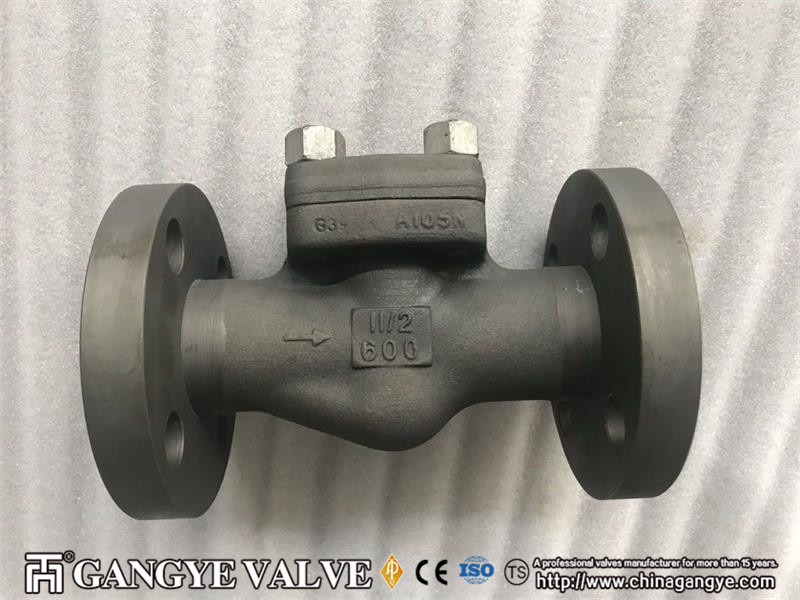

High-Performance Forged Steel Check Valves | API 600 & ASME B16.34 Certified

Gangye’s premium forged steel check valves deliver unmatched durability and precision for high-pressure industrial pipelines (10NB–50NB). Engineered to BS 5352 and ASME B16.34 standards, our valves are ideal for oil, gas, and water systems with pressure ratings up to ANSI 800#/2500 LB.

Core Advantages Driving ROI:

✅ Zero-Leak Guarantee: Hard-faced trim materials ensure perfect sealing & extended service life.

✅ 3-in-1 Versatility: Choose piston, ball, or swing check configurations for optimal flow control.

✅ Global Compliance: Certified to ISO 9001, API 600, CE, and TS standards.

✅ 18-Month Warranty: Industry-leading protection against defects.

Technical Specifications

- Pressure Rating: 150 LB – 2500 LB (ANSI 800#)

- Size Range: ½” to 2” (10NB–50NB)

- Temperature Range: -20°C to +232°C (-4°F to +450°F)

- Materials: A105 Carbon Steel • F304/L & F316/L Stainless Steel • LF2/F11/F22 Alloy Steel

- End Connections: Threaded • Socket Weld • ASME B16.5 Flange

Why Engineers Choose Gangye Valves

1️⃣ Superior Flow Control: Lift-type disc with guided actuation for instant flow-direction response.

2️⃣ Dual Bonnet Options:

- Bolted Bonnet: F316L/graphite spiral wound gasket

- Welded Bonnet: Full penetration strength joints (customizable)

3️⃣ API 598 Tested: Every valve undergoes rigorous pressure and sealing tests.

Global Standards Met:

- Design: API 6D, ASME B16.34, BS 5351

- Testing: API 598 • MSS SP-25 marking

- Dimensional Compliance: ASME B16.5, B16.10, B16.11

CTAs for Conversion Optimization:

🔧 “Need Customized Valve Solutions? Request Your Free Technical Consultation Today!”

📞 “Call +86-13676738198 📧 sales@chinagangye.com for Bulk Order Discounts & OEM Options”